PLAIN END FOR LOWER COST CONSTRUCTION

Naylor Spiral Buttweld and Lockseam Spiralweld Pipe can be furnished with plain, square-cut ends

for field butt welding. The Naylor structure provides accurate diameter, preserves true cylindrical

form, with ends that always match correctly, makes possible the welding of plain-end pipe.

PLAIN END WITH BACK-UP RING

To facilitate field welding of plain-end pipe, a back-up ring can be supplied.

NAYLOR STEEL FLANGED JOINTS

Naylor steel flanges are designed to slip over the ends of spiral buttweld or lockseam spiralweld pipe for welding. They can be furnished drilled to American Standard (125 lb.), to the Spiral Pipe Standard(SPS), or drilled to meet special requirements.

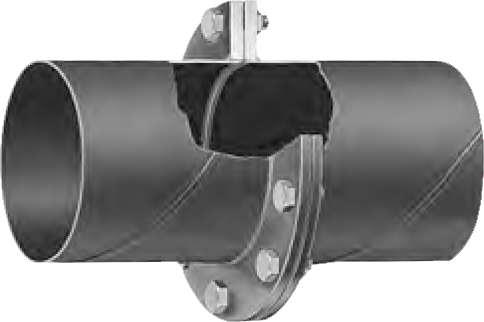

MECHANICAL COUPLINGS FOR GROOVED END PIPE

Standard weight grooved ends are furnished to permit use of this type of coupling on both spiral buttweld and lockseam spiralweld pipe. Simple and easily connected, this joint provides some flexibility and allowance for expansion and contraction. It will not allow the line to blow apart as the coupling is anchored in the groove.

MECHANICAL COUPLINGS FOR PLAIN END PIPE

The outside weld bead on the pipe is ground smooth for a suitable distance to enable the coupling to properly seat on the plain end pipe. This coupling will take up considerable expansion and contraction, and permit some flexibility at each joint. On exposed lines subject to temperature variations, it is often necessary to provide harnesses to prevent the coupling from working itself off the line.

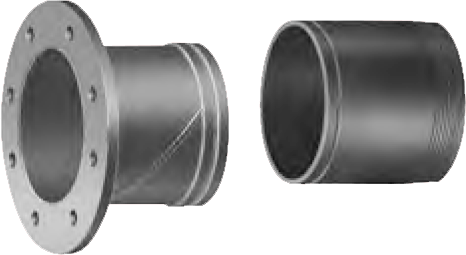

SHORT NIPPLES OR ADAPTORS

Naylor short nipples or adaptors for spiral buttweld or lockseam spiralweld pipe are standardized at one foot in length, but can be furnished longer or shorter. Practically any combination can be made, permitting coupling of any type to be changed to another. Illustrations show flange-to-groove and groove-to-thread. Other units are available to transpose to any connection in this section, or special connections where required.

DREDGING SHORE PIPE JOINT

A standard connection for dredging shore pipe using taper band and lug type construction. The Naylor taper is accurately shrunk to size either from cylindrical stock or directly on plain end pipe. This thickens the small end of the taper where most wear occurs. On the female end, the reinforcing band is set back slightly from the end to allow a slight flaring action which improves the seal. Lugs are ample in weight and size with plenty of hand room. This connection can be used with either spiral buttweld or lockseam spiralweld pipe.

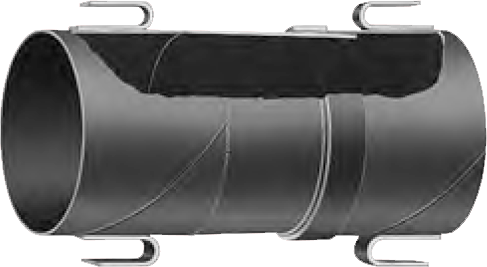

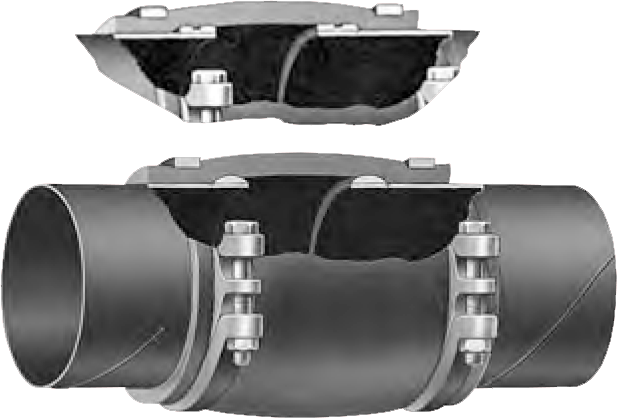

PONTOON PIPE JOINT FOR RUBBER SLEEVE CONNECTION

Conventional half-oval band type pontoon pipe joint. These half-ovals are accurately sized and fit close to the wall of the pipe. The outside weld bead on the spiral buttweld pipe is ground smooth a sufficient distance to allow the rubber sleeve to fit snug against the pipe wall. Upper illustration shows an alternate type construction using slip-over grooved ends for retaining the rubber sleeves. This permits the use of Naylor Heavy-Duty Wedgelock couplings in the line where rubber sleeves are not required at every joint for flexibility. Cost is reduced because the Wedgelock is less expensive and operating efficiency is improved by reducing the friction loss.