The year was 1925. After 13 years of innovation and refinement, Carl Naylor was ready to form his own company.

He had long been interested in the manufacture of pipe, having built his first machine to make straight lockseam pipe in 1912, while working in the sheet metal shop of Robertson Brothers Manufacturing Company.

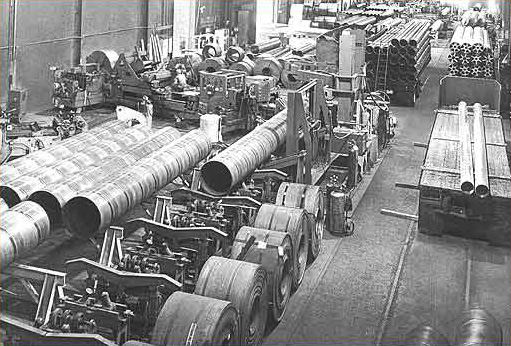

By 1919, he had perfected the first machine ever to produce a lockseam spiral pipe. A pipe literally wound on a lathe-turned mandrel, with the edges interlocked into a rigid four-ply seam, a pipe with an accurate diameter—as round as the arbor on which it was turned.

So it was on March 13, 1925 when Mr. Naylor formed Naylor Pipe Company. Starting in a small lockseam pipe fabricating shop in a corner building at 92nd and Avalon on Chicago’s South Side, Mr. Naylor and a handful of employees began to produce a unique and distinctive pipe.

Two years later, in 1927, the young company introduced the first welded spiral pipe, having developed a process to weld the lockseam spiral automatically during production. The results of this innovation completely revolutionized the pipe making field. There was now a lightweight pipe that could be used as a pressure vehicle.

As a result, Naylor’s Lockseam Spiralweld Pipe was used extensively during the 1930’s and 1940’s throughout the then rapidly expanding oil fields for gas gathering lines and for surface casing. It helped the Allies during World War II, by supplying fuel oil and gasoline to our advancing troops in North Africa, Europe, and the Pacific.

Those early years also saw the company continue to add services and products to the line, manufacturing pipe in increasingly heavier gauges, and providing new products such as, the exclusive, patented Wedgelock Coupling. By the mid 1940's, Naylor established a complete fitting and pipe fabricating department to serve other customer requirements.

As the product line continued to expand, so too did the opportunities. During the 1950's and 1960's, Naylor Pipe found widespread use in such new markets as construction and mining, by proving to be an ideal answer to such applications as air and water supply, product lines and hydraulicking.

Although years of success continued to prove the tremendous value and popularity of Naylor's Spiralweld Pipe, it was not without its limitations. So, by 1970, Naylor introduced Spiral Buttweld Pipe. This versatile pipe was able to be produced in much heavier gauges and larger sizes to meet the piping needs of the 1980's and 1990's. In fact, today it is available in wall thicknesses as heavy as 1/2" and in diameters as large as 8 feet.

While other pipe manufacturers have come and gone, Naylor continues to grow and prosper, concentrating on what it does best…the manufacture of spiralweld pipe. Much credit goes to the three presidents who guided the Company through such troubled times as the Great depression, three wars, and numerous recessions: Carl Naylor from 1925 to 1950; Newt Turney from 1950 to 1971; Bill Skeates from 1971 to 1999 and John Czulno from 1999 to present.

But even more important, are all the men and women who have served the company down through the years. To them and to our many customers we pay tribute, fully aware of our past accomplishments and ready to achieve even more in the future.